Solutions » Kiosk Solutions

Kiosk Solutions

Solutions for Kiosk Systems in the Bulk Goods Industry

Field of Application

- Weighing slips

- Barcode labels

- Delivery Documents

- Shipping Notes

Highlights at a Glance

- Built in cutter for attended or unattended cutting

- Heavy duty 24-wire dot matrix printer with IntellidriveTM – Technology

- Compact flat bed design with 94 columns and print bar

- High print performance: 600 cps (10 cpi) 500 pages/hour 40,000 pages/month

- Up to 9 excellent copies (1+8)

- Printing width up to 165 columns (10 cpi)

- Easy user operation via macro functions

- Personality Modules (interfaces) with emulations for major host and network environments

PP 803C in Kiosk Systems.

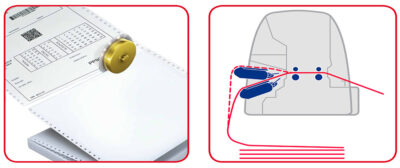

Printing-Cutting-output

Kiosk systems in the bulk goods industry are print output systems without operator guidance or in self-service operation of weighing systems. PP 803C printers with integrated paper cutters are often used for receipt printing when weighing lime, sand, gravel, waste, liquids, agricultural products, etc, installed in closed housings.

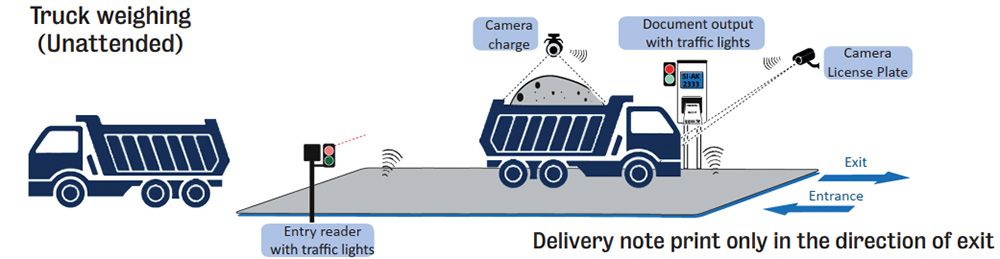

Printing on Weighing Systems without Operator Guidance (unattended).

When the transport vehicle enters, the vehicle is initially weighed empty. The difference in load during weighing at the exit, is reported to the voucher kiosk. Activation takes place from the outside, using chip cards, key codes or similar. The document data is processed and printed (e.g. net / gross data). There is a controlled separation of the printing sections and the receipts are issued for removal by the driver.

Kiosk systems are subject to constantly changing environmental influences such as temperature fluctuations, different air humidity or strong vibrations. In addition, most operator-less kiosk locations are often located hundreds of meters away from the central office. A high level of reliability and stability of the components used are required here. For receipt printing, precise positioning for printing and separation is also required.

The reliable feeding and output of the print media of the PP 803C, as well as the paper run monitored by the IntelliDrive (R) guarantee smooth operation. An exact positioning of the cutting edge and a straight cut guarantee a precisely created weighing document.

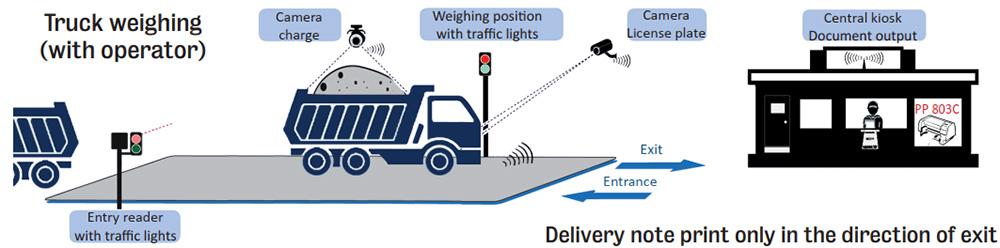

Printing on Weighing systems with operator guidance.

Usually in this application also the scale is 100 to 200 meters away from the Central Office for the document output station. When the transport vehicle enters, it is initially weighed empty. The difference in load during the second weighing at the exit is reported to the weighing house. The travel time of the vehicle from the scales to the weighing house is used for document creation and printing. The print slip is checked by the operator and given to the driver.

Application Brochure