Know how » PDF® Direct Printing with Microplex

PDF® Direct Printing with Microplex

Direct PDF® printing with support for paper handling functions is a novel method of printing single and multi-page PDF® documents with Microplex printers.

With the Microplex printers of the latest controller generation (MPC 3.6, 7.x, 8.x) it is possible to print PDF® data directly.

On Microplex printers, PDF® data output is unchanged. You receive a 1:1 printout as the data was generated.

In the case of delivery documents with barcodes, for example, these are printed legibly in the ratio provided. For this purpose, the original PDF® data is transferred directly to the printer.

This ensures your system independence, no Windows drivers are required. The PDF® data is printed in the resolution of the printer.

In addition to the well-known emulations such as thermal printer emulations IGP, ZPL, EPL, etc. as well as laser printer emulations such as PCL5, Kyocera Prescribe, IPDS and many more, Microplex printers now also support direct printing of PDF® data.

The PDF® format is often used for printing business documents when these data are generated externally by e.g. customers, service providers etc. This data should be used as unchanged as possible (tamper-proof).

When using printing software and/or drivers, there is always a risk that the print data may be slightly altered by these programmes. For example, unwanted scaling can occur due to the physical properties of the printers.

This can potentially render barcodes unreadable and thus interrupt the logistics chain or lead to costly rework. This is not the case when using PDF® direct printing with a Microplex printer.

Paper handling with Microplex PDF® Direct Printing

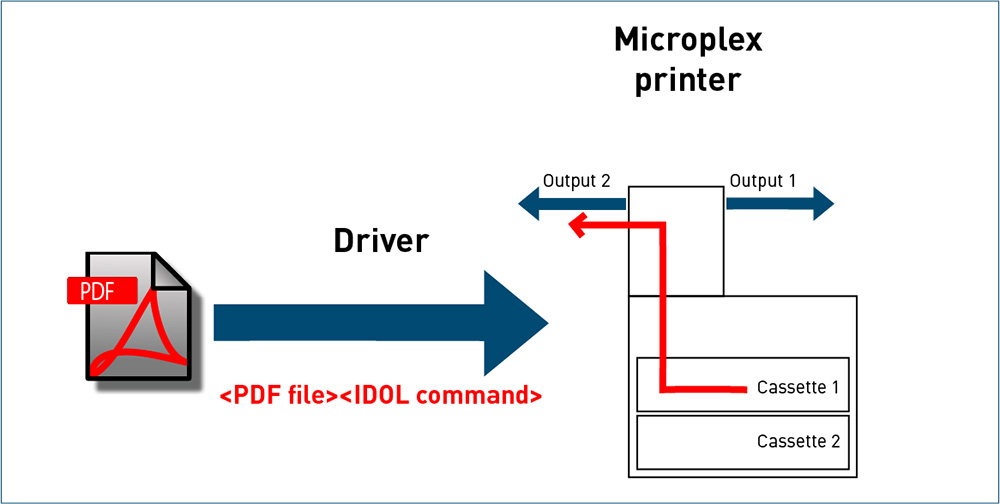

Paper handling with IDOL commands

IDOL commands with paper handling information can be prefixed to the PDF® file. This transfers paper feed, paper output, simplex/duplex printing, format etc. to the printer.

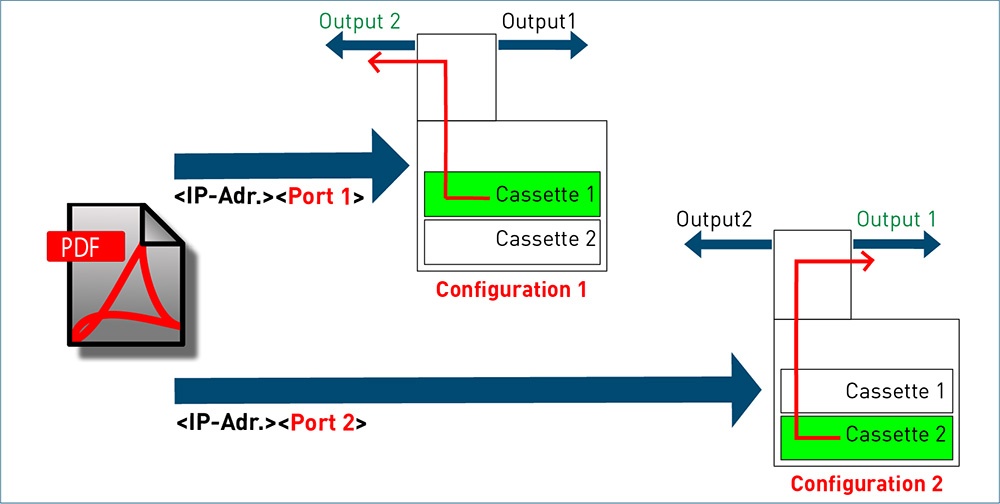

Configuring paper handling easily

Several user configurations (port macros) with different basic settings can be defined in a Microplex printer and activated with the PDF® file via port printing.

PDF® Direct Printing in Plant Engineering

Microplex printers with PDF® direct printing work together with automatic systems. Microplex printers can be intelligently controlled and integrated as an active part of a plant control system for the synchronisation of logistical processes. Direct printing of PDF data can also be combined with the Status-Out and GPIO (PLC Control) options on a Microplex printer.

Here, page acknowledgements can be automatically reported to the system or, if required, e.g. the printout can be released via an external PLC signal. Microplex printers can thus be integrated into production systems without restriction. The printer then communicates directly with the controlling system, either via electrical signals GPIO (PLC control) or by means of text messages via the data interface (status out).

The direct printout of PDF® data serves not only to protect against manipulation, but also to improve the performance of the entire system. PDF® data that are already available and stored in a system database, for example, can be sent directly to the printer. There are no additional processing steps, you gain speed and reliability.

PDF® data generated dynamically by the customer’s system can also be passed on to the printers in the same way without loss. It is guaranteed that the data is printed in the correct layout, with the correct fonts and, if applicable, logos. The system control merely adds the commands for paper handling (paper feed, paper output, simplex/duplex printing, format, etc.) or uses port macros for control in which the corresponding specifications are stored.

Scaling

In addition to the unchanged output, PDF files can also be output scaled using IDOL commands. This is always done while maintaining the aspect ratios so that no distortions occur. For example, A4 documents can be output with „shrink-to-Fit“ on A5 paper. The scaling takes place in the printer. It is also possible to scale PDF files to any larger format using „scale-to-fit“. For this purpose, a PDF file is transferred to the printer in a data stream together with an IDOL command. The scaling always applies to a print job.

Encrypt

With the Microplex printers it is possible to print encrypted PDF files. For this purpose, the encrypted PDF file is transferred to the printer together with the password in an IDOL command. If the password is correct, printing begins immediately. No interaction on the printer is necessary. If the password is incorrect or missing, the printer stops with an error message. This ensures that the desired print order is adhered to.

The advantages at a glance:

- Cassette selection via predefined user configurations

- Configuration of print settings via convenient web interface

- Paper handling information can be specified individually for each print job.

- Independent of the operating system, PDF® versions 1.3, 1.4, 1.5, 1.6, 1.7 2.0 are supported.

- Exact printout of the data as defined in the PDF®, the data is not changed via a driver

- Integration into production systems via GPIO (PLC control) and status-out

Downloads

| Link | Other languages | Size |

|---|---|---|

Application Brochure – Adaptation and Customization Application Brochure – Adaptation and Customization | 1.74 MBytes | |

PDF® Direct Printing with Microplex PDF® Direct Printing with Microplex | 497 KBytes |

Know How